Our Blog On-Demand

Content

Knowledge Hub

Knowledge Hub

Properly permitted, your emergency generation—EG—is both a reliability asset and a revenue generator. EG provides a great opportunity to earn revenue and save on energy costs through demand response (DR) and demand management programs.

The path from emergency generation to revenue generation, though, may seem like a complex, confusing, and occasionally contradictory thicket of state and local environmental regulations. Few organizations fully understand the scope and intricacies of EG regulation, which often results in misinformation, missteps, and missed revenue opportunities.

Fortunately, CPower’s extensive experience and knowledge base has led hundreds of organizations through the jumble of regulations and provided a clear path to monetizing EG assets. This webinar covers everything today’s energy managers and engineers need to to know to maximize the benefits of their EG portfolio. It includes:

Join Ray Berkebile, CPower’s nationally recognized EG permitting expert, and CPower engineer Alison Keefe as they lead this in-depth look at how your EG assets can generate revenue for you, too.

Download the slides: Leverage Your Generator Assets To Earn Revenue Webinar (PDF)

With the season’s first snow on the ground and the official start of Winter just days away, it’s a good time to look back at how the PJM Interconnection performed over the summer, and how it’s projected to perform in the months ahead. While we’re at it, let’s look a little further into the future, to the introduction of full-time Capacity Performance in DY 2020/21.

Early summer heat gave way to a milder late summer.

The 2017/18 PJM Summer DR season began with warmer than usual early summer temperatures and system loads. Although typically PJM’s five system peaks occur mid-July through August, this summer we saw two of the system peaks occur in early June and the others in July. Which meant that DR customers needed to be on alert and ready for emergency events earlier in the summer then they are typically used to. Peak shaving customers also had to be ready to predict early peak days and potentially may have missed them. This may mean higher Peak Load Contribution (PLC) values for the next power year. PJM’s Five Coincidental Peaks (5CP) for 2017 that are used to determine capacity costs through PLCs are shown in the table below.

| DATE | HOUR | PJM LOAD (MW) |

| 7/19/2017 | 18 | 145,331 |

| 7/20/2017 | 17 | 145,097 |

| 7/21/2017 | 17 | 142,003 |

| 6/12/2017 | 18 | 140,660 |

| 6/13/2017 | 17 | 138,365 |

The summer ended without PJM declaring any emergency events, which means Limited DR customers needed only to comply with an hourly test event to show program compliance. Extended Summer DR customers still have May 2018 to be on call for any emergency events, and Annual DR and Capacity Performance (CP) DR customers have the balance of the 2017/18 power year to be on call for emergency events.

Colder and snowier winter than last year projected by PJM.

In a recent press release, PJM states that weather patterns indicate a strong likelihood of a continuation of the cool Summer and Fall temperatures into the Winter. This could bring parts of the PJM territory periods of cold polar blasts, and bring greater chances for winter precipitation than we had experienced the past few winters.

But no worries. PJM reminds all end users that although it anticipates a colder winter—and has forecasted peak loads just over 135,000 MW—it has ample resources to meet the needs of the system demand, with just under 185,000 MW of dispatchable generating capacity.

This is good news for Annual and CP DR customers anxious about potential Winter emergency events. Although all DR customers should be prepared to respond if needed and feel confident in their ability to perform, they should take comfort in PJM’s ability to meet demand and avoid the system entering into an emergency situation.

PJM’s Capacity Performance product is the answer to grid reliability.

As you’re probably well aware, PJM ushered in the new Capacity Performance (CP) product at the start of the 2016/17 season and will transition to a full CP-only market starting with the 2020/21 season. This CP product was PJM’s response to the early 2014 extreme winter weather known as the Polar Vortex. That winter exposed threats to PJM’s ability to meet winter demand as many generation units were unavailable or unable to meet system needs. The CP product now imposes greater requirements on all capacity resources to ensure availability and reliability. It is because of the new CP product that PJM feels even more confident in being able to meet both Winter and Summer system needs going forward.

CPower discusses the Capacity Performance product, the new market, and dissects some myths about the product and what it means to the DR community in its White Paper as well as part of its ongoing webinar series. We highly recommend checking both of them out to help answer any questions you may have on the CP program and your ability to participate in it.

To learn more about PJM’s changing market or about how to be better prepared for potential grid instability this summer, contact Dann or any member of the CPower’s PJM Team.

successfully seized the opportunity to earn additional revenue for the school through demand response

Virginia State University (VSU), founded in 1882, is one of Virginia’s two land-grant institutions. It boasts a current student population of approximately 4,700. VSU’s 231-acre campus includes 11 residence halls, 18 academic buildings and a 412-acre working farm used for agriculture research. VSU features academic environments within six colleges and is ranked No. 12 institution in the United States for historically black colleges or universities (HBCUs) by College Choice.

Ms. Jane Harris, Assistant Vice President for Facilities and Capital Outlays, was enthusiastic about PJM Interconnection’s demand response (DR) program, which pays organizations for curtailing energy use during times of high demand that strain the region’s electrical grid. She felt VSU had a good probability of a successful outcome, generating revenue to fund needed campus upgrades. In 2014, she was given the go-ahead to enroll in DR.

To make sure the university’s DR participation had a successful launch, Ms. Harris built a leadership team which included the facilities management staff and building managers. The team was led by one of her project managers, Mr. George “Bubba” Bowles. Mr. Bowles brought deep knowledge of utility operations and was tasked with managing the project. CPower, represented by Ms. Leigh Anne Ratliff, brought unmatched expertise in PJM’s DR curtailment program.

Mr. Bowles developed a demand response action plan that included a survey of all campus buildings, and the energy technology available in each building. The campus infrastructure was not designed to curtail energy quickly and easily. Not every building was equipped with sub-meters and automated controls, and some generators could supply power for only emergency lighting. Nonetheless, Mr. Bowles felt that with proper planning, training, and communication, VSU would succeed.

Communication–specifically communicating the program’s benefits–proved to be the key component of the plan. Months before the first test event, which required the university to reduce their usage at a particular date and time, the leadership team undertook an extensive communication program that targeted the university’s building managers, campus facilities maintenance contractor, information technology staff, facilities inspector, campus safety officer, and Yourdonus James, Conference Services Manager, who schedules outside groups for events on campus. Each step of the plan was explained in detail, emphasizing the real and substantial benefits the university would receive from DR. As the test date approached, specific tasks were assigned to facilities staff and the safety officer that would help VSU meet their targeted curtailment goals, from turning on generators to turning off the breakers to entire buildings. Ms. James explained that she was concerned when first informed of the demand response program, but the actual test proved transparent with no noticeable impact on her clients.

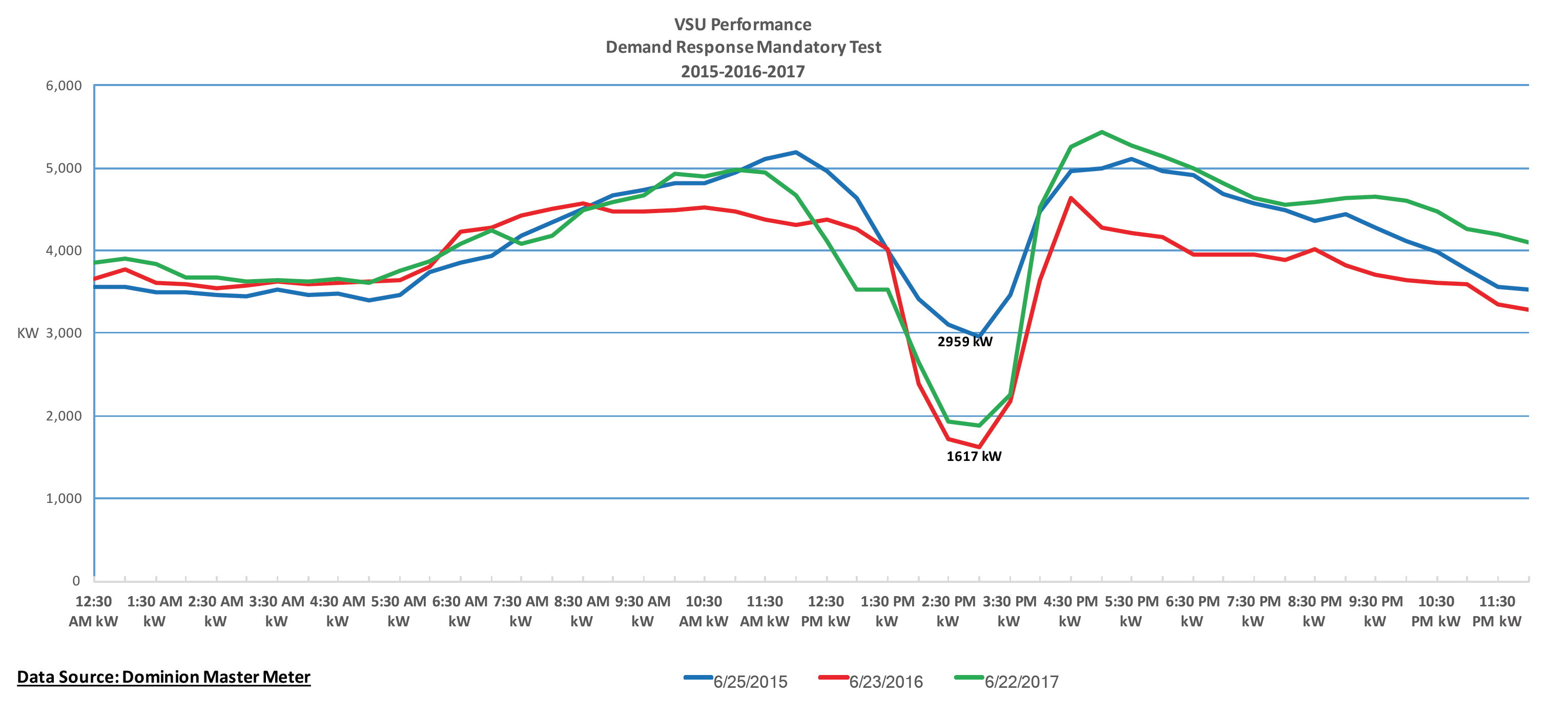

In June 2015, VSU participated in its first test event and exceeded its curtailment goal. In 2016, they set their curtailment goal even higher and exceeded that as well. In 2017, they set their goal higher.

The event test for 2017 was scheduled for a June afternoon at exactly 2:00 p.m. Around noon the plan, improved and streamlined over the past two years, was put into action. HVAC was cut off to 19 buildings, which were pre-cooled. In 10 buildings, energy could not be curtailed, so building managers enlisted the tenants to close blinds, turn off lights and computers, and schedule a late lunch to reduce usage during the test. Power to another 19 buildings was shut off completely.

As the plan proceeded, they faced an “11th-hour-and-59th-minute” challenge that threatened their continuing success. The team learned that at that moment, VSU was hosting 900 potential students at all academic buildings, including Daniel Gymnasium, one of the buildings targeted for complete shutdown. Not only that, but the students were to be sent out to explore any building of their choosing–many of them already curtailed–at exactly 2:00 p.m. Shifting gears, the team quickly “un-curtailed” Daniel Gymnasium.

At 2:00 p.m, with the temperature outside registering 87 degrees, VSU began its test curtailment. VSU had committed to curtailing their load by approximately 4 MW. By the time the event ended, of a total campus load of 6 MW, VSU curtailed 4.5 MW–an unprecedented 75% campus-wide load reduction.

The one factor that all team leaders agree was critical to success is effective communication. By communicating clearly not only what had to be done, but why, the team was able to get buy-in from the entire campus community. Ms. Harris made it clear that the revenue generated by DR would benefit them directly–they would have the funds to do things that they normally wouldn’t be able to afford. Each building manager became an enthusiastic stakeholder, which assured campus-wide success. As Mr. Bowles notes, “We make it easy for them to say ‘Yes’ by showing that it benefits them.”

Three years of increasingly profitable participation has funded a number of university facility projects. Chief among them are upgrades to two residence halls in the historical section of campus. The upgrades turned residence halls into destinations for which students now compete for assignment.

VSU has also been able to pursue energy efficiency projects that result in permanent curtailment and energy savings. Residence halls are being upgraded to highly efficient LED lighting, and generators are being upgraded to full building operation. Both upgrades, besides saving energy, have the potential for adding more revenue from DR participation.

Perhaps more importantly, the success of DR at VSU has helped create a culture of energy conservation and sustainability on campus. Faculty, staff, and students increasingly embrace programs such as recycling, energy conservation, and research into environmental programs and economic development. “Virginia’s Opportunity University” is also becoming “Virginia’s

Sustainability University,” true stewards of the earth that anchors their mission.

The Customer: Desert Water Agency, Palm Springs, California

The Desert Water Agency (DWA) is a not for profit government agency providing water to the desert resort community of Palm Springs, in the Coachella Valley, as well as adjacent areas. Nearly all of the water that is used in the Coachella Valley comes from a groundwater basin, or aquifer estimated to contain about 30 million acre-feet of water. DWA pumps water using 29 wells spread throughout its retail area and delivers it to 23,000 water connections serving approximately 106,000 residents and businesses.

DWA embraces sustainable energy resources, including hydroelectric and solar, to power its pumps and generate energy savings. A solar field comprising 4,500 ground-mounted fixed tilt panels produces just over a megawatt of energy. The solar facility powers their Operations Center and Water Reclamation Plant and is projected to save the Agency and its ratepayers about $6 million in energy costs during its lifetime.

The Challenge: Tap the Demand Response Revenue Stream

The demand response program offered by CPower pays customers for reducing their energy usage upon same-day notification of a possible grid event. DWA understands the benefit of earning additional revenue by curtailing their power load and using that revenue to further offset energy costs. The key to DWA’s successful participation was technically implementing a curtailment program with the least possible disruption to its operations and its customers. Wells throughout the city that could participate in the program would be turned off when CPower issues a curtailment notification.

That left them with one important question: “Can we survive three to four hours of having wells shut down and still be able to refill our reservoirs to meet customer demand?”

The CPowered Strategy: One Well at a Time

Thankfully, with CPower’s help, the answer was “Yes.”

DWA chose CPower as their demand response provider to manage their participation in the demand response program. CPower provides a team of energy experts to review the Agency’s operations and energy goals. Together, DWA and CPower developed an energy management strategy that gives DWA the tools to optimize their participation in the program.

The strategy called for DWA to start with a small number of wells, to familiarize themselves with the curtailment process with minimal impact on day-to-day operations. As DWA’s staff became more comfortable with the process, more wells were added, until all eligible wells—25 of their total of 29—are now actively participating and generating revenue for the Agency.

CPowered Solutions: Power Empowerment

Understanding the Agency’s preference for autonomy over automation, CPower empowered it with the tools to control its energy spend and demand response participation. The Agency can turn individual sites on and off at will upon notification through their supervisory control and data acquisition (SCADA) software to implement the custom-designed energy strategy developed with CPower’s experts. Perhaps best of all, the Agency can manage it all from their central Operations Center, without dispatching staff to well sites under a grid-stressing desert sun.

CPower collects utility meter data for each of DWA’s sites and supplies them with quarterly performance data. These data provide DWA with an understanding of each site’s base load value. The Agency can use these data to decide their optimum load curtailment commitment for each month of the program.

The Results: An Oasis of Cost-Saving Revenue

DWA typically nominates a changing rotation of eight wells each month into the program. The total monthly load drop amounts to about 2.5 MW. This is a significant commitment that helps relieve stress on the electric grid.

The program also provides DWA significant financial incentive for their participation. During a recent six-month period, May-October, they received $105,872.68 in payments for their participation. These incentives allowed them to further offset their energy costs, to the benefit of their customers.

Just as importantly, perhaps, DWA enjoys the total commitment of CPower’s dedicated California energy market experts. The Agency knows from experience that CPower will support their energy goals at every turn, with an energy strategy custom-made to meet their unique requirements.

Download a PDF version of this case study

The Electric Reliability Council of Texas (ERCOT) and independent market analysts agree on at least one thing: there will be about 4,200 MW less fossil fuel capacity in the Lone Star State in 2018, a decrease that can be attributed to the approved retiring of three coal-fired generation plants–Monticello, Sandow, and Big Brown.

Exactly how the decreased capacity reserves will affect the Texas market is less agreeable, at least for now.

ERCOT maintains a capacity reserve margin target of 13.75% of peak electricity demand so the grid operator may serve electric needs in the case of unexpectedly high demand or levels of generation plant outages.

Analysts like Potomac Economics, an independent market monitor for ERCOT, predict the retiring generation plants in Texas will lead to the grid’s capacity reserves dipping below ERCOT’s margin target.

Potomac’s prediction is at odds with ERCOT’s official forecast for capacity reserves in 2018, at least now.

Last May, ERCOT released its bi-yearly Capacity, Demand, and Reserves (CDR) Report, which projected the grid’s reserve margins to be above 18% until 2022 when the margin falls to 16.8%. The report, however, was published several months before the recently announced coal retirements.

After doing the math and subtracting the capacity associated with the retiring units from the 2017 CDR report’s forecast, a breach of ERCOT’s target reserve margin seems possible.

So ERCOT’s capacity reserve may drop below the 13.75% target. What does that mean?

We’ll likely learn the official answer in mid-December 2017 when ERCOT releases an updated CDR report to address what the loss of capacity from retired generation plants will mean to the grid.

Until then, we can make a few educated guesses on how the Texas market will react to decreased capacity based on the market’s recent history.

In the last 10 years, ERCOT’s reserve margin projections have dropped to single digits 10 times, reaching a recent low of 5.8% in 2012. The market has repeatedly bounced back from low projections. It’s worth noting, however, what happens when ERCOT’s capacity reserves actually fall below the grid operator’s target reserve margin.

That last happened in 2011, which was also the last time ERCOT’s scarcity pricing mechanism was triggered.

Scarcity pricing introduces a price floor and price cap to the market when an electricity supply emergency causes concerns of forced power cuts (called emergency load shedding) throughout Texas. When ERCOT’s reserves hit 2,000 MW as they last did in 2011, scarcity pricing sets an automatic cap at $9,000 per MWh.

Now let’s analyze who benefits from scarcity pricing. The short answer is generators. In an energy-only market like Texas, generators make money when the price of electricity spikes. Over the last several years, demand for electricity in Texas has set numerous peak load records, including new monthly highs in July and August 2017.

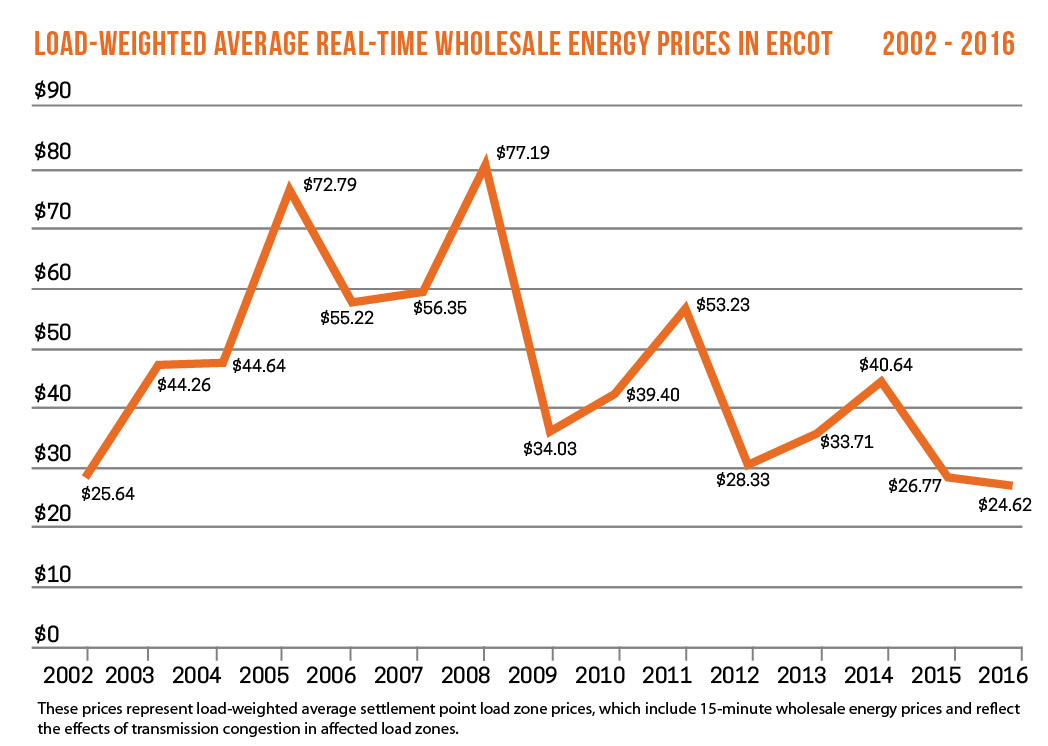

Power prices in Texas, however, have remained relatively stable. In fact, ERCOT reported that 2016 saw average wholesale prices in its real-time market hit an all-time low (see chart below). Increased wind production, which accounted for less than 1% of ERCOT’s power in 2003 rose to 15% in 2016, continues to put downward pressure on prices, as does cheap natural gas supply.

The drop in capacity reserve in 2018 may lead to the kind of price spikes that generators have been waiting for, but generators will not be the only beneficiaries if wholesale prices see a significant rise.

If triggered, scarcity prices will be translated into ERCOT’s day-ahead ancillary services capacity procurements. That could mean financial opportunity for businesses who participate in ERCOT’s Load Resource demand response program, which pays businesses to be on call to curtail their energy use on short notice when the grid is stressed or electricity prices are exceptionally high.

Load Resource, ERCOT’s go-to ancillary service demand response program, already has the potential to pay businesses 2-3 times more than reliability-based demand response programs in Texas like the Emergency Response Service (ERS) program.

If scarcity pricing triggers in 2018, that potential payoff may be a lot bigger in Texas.

Part 1, “ERCOT Fundamentals: DR 101,” introduces you to DR in ERCOT and covers topics ranging from market structure to participating with automation and emergency generators.

Part 2, “Strategies for Maximized Results,” takes your DR knowledge to the next level and shares some important out-of-the-box methods for maximizing your value.

Both webinars are FREE and now open for registration.

For most of the last two decades, demand response in California has been largely procured and operated by the state’s electric utilities.

That trend is changing.

Demand response in California is currently experiencing significant changes as regulators implement measures to expand the state’s pool of energy resources and assimilate these resources with the California Independent System Operator’s (CAISO) markets.

This regulatory reform has created new opportunities in California for demand response programs, which pay businesses for using less energy when the grid is stressed or electricity prices are high.

The Demand Response Auction Mechanism

The Demand Response Auction Mechanism (DRAM) was developed in 2014 under the guidance of the California Public Utility Commission (CPUC) in an effort to harmonize utility-based reliability demand response with CAISO, the state’s grid operator.

In December 2014, the Commission issued D. 14-12-024 which requires the state’s IOUs: Southern California Edison Company (SCE), San Diego Gas & Electric Company (SDG&E) and Pacific Gas and Electric Company (PG&E) to design and implement Demand Response Auction Mechanism (DRAM) pilot programs in 2015 for 2016 capacity (DRAM I or 2015 DRAM) and in 2016 for 2017 capacity (DRAM II or 2017 DRAM). The three utilities recently completed a solicitation for 2018/2019 capacity (DRAM III) procuring over 200 MW of DR resources across the state.

Now in its third year, the program seeks to allow CAISO to add reliable demand response resources to areas of California where electric reliability may be at risk.

DRAM is a pay-as-bid program with three goals:

1)Fully integrate DR resources with the CAISO energy market

2) Test whether third parties can bring these resources to the table without structured utility programs

3) Allow residential resources to participate directly in the CAISO markets

The DRAM program also provides market participation testing from a broader base of distributed energy resources, including behind-the-meter storage. Under DRAM, these resources have the opportunity to behave not just as system capacity, but also as local and flexible resources.

California’s recent actions aim to revise the market’s existing demand response program structure and are an indication that DR has an important role to play in the state’s future.

The best way for an organization to take advantage of the DRAM program and the opportunities available in the California Market is to consult a trusted demand-side energy management company.

Such a company can evaluate an organization’s facilities and determine its curtailment capabilities. Next, they can explain in full the many demand response and demand management programs that are available in the California Market and help determine which offer the particular organization the best chance for curtailment success.

To learn more about how CPower can help your organization earn with the Demand Response Auction Mechanism program, please visit CPowerEnergy.com/dram-california.

To continue learning about how the California grid is changing to meet the needs of the future, read: The Evolution of The California Energy Market: How Demand Response and Demand Management will Play Integral Roles in The Golden State’s Energy Future