Phoenix ET — Leveraging Link API to Increase Customer Energy Savings

Case Study: How Phoenix Energy Technologies leverages CPower’s exclusive building automation tool to increase energy savings in demand response

building automation tool to increase energy savings in demand response

Phoenix Energy Technologies is a leader in smart buildings and connected machines. They control, manage, and monitor assets such as HVAC, lighting, refrigeration, industrial, and consumer-facing machines. Phoenix enables its customers– retailers, universities, theater, and grocery chains, and more – to accomplish their savings goals by providing best-in-class software that monitors and controls assets with minimal additional hardware.

Phoenix has built a stellar reputation on its ability to provide customers with significant energy savings. Could CPower help them provide even more with one particular customer?

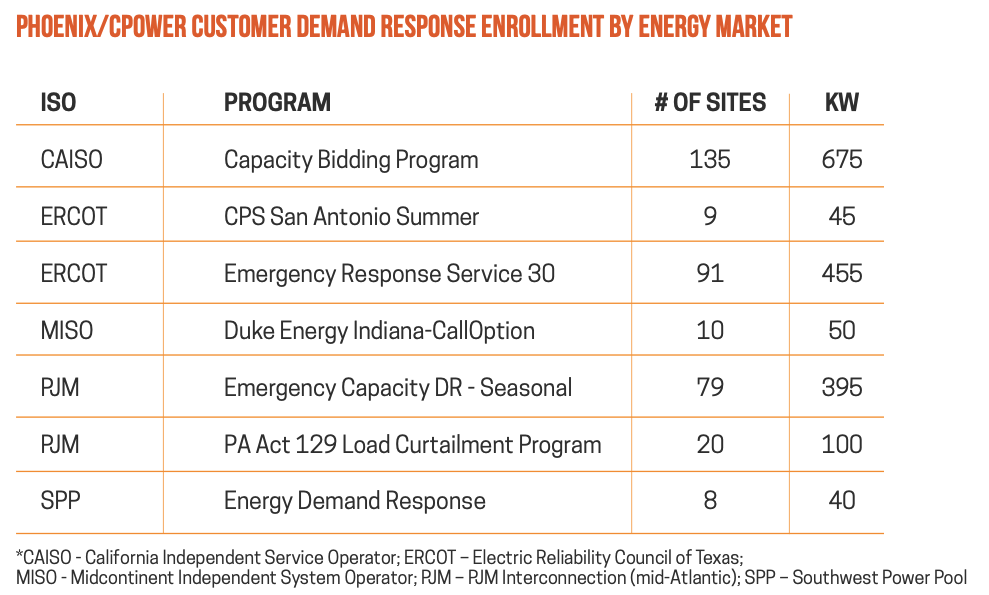

CPower and Phoenix have a national big-box retailer as a customer in common. CPower has enrolled more than 1.7 MW at more than 350 of the customer’s sites in Demand Response (DR) programs nationwide. These same sites employ Phoenix’s Enterprise Data Xchange (EDX) Smart Building Platform to automatically optimize building performance, reduce energy consumption, and improve customer comfort.

What it couldn’t do, however, was perform one crucial task: Automate demand response. Each of those 350+ sites participating in programs – such as Capacity Bidding Program in CAISO, ERS 30 in ERCOT, and even the utility program Act 129 in Pennsylvania – performed their curtailment activities manually. This left the door open for missed opportunities, missed savings and revenue, and in California, which sees multiple events each summer, a fair amount of frustration.

With CPower providing DR services and Phoenix providing energy management services, the obvious solution was CPower’s Link API, our proprietary application programming interface. Link seamlessly integrates our automated metering and dispatch processes with any and all building management systems, including Phoenix’s EDX.

Link creates an integrated automatic DR platform that provides customers with the ability to enact predetermined load management measures at close to a moment’s notice, to precisely the degree they need. Another important plus: Link API is one of the few automated demand response tools that meet California’s Open Automated Demand Response (OpenADR) open source requirements. With 135 California customer sites, this was a critical consideration.

To ensure secure, reliable performance of the new ADR system, Phoenix engineers completed a thorough two-stage certification process:

• Link Adapter Stage 1 Testing – Testing to verify that the Link adapter on Phoenix’s control platform is securely communicating with CPower’s servers and properly interpreting DR messages

• CPower Link Final Certification – Full end-to-end testing, sending signals from Dispatch to the sites’ building controls through the Link adapter, initiating a load drop test, and ultimately reinstating normal operations

Only after successfully passing both stages did CPower certify Phoenix’s control platform’s Link adapter ready to support this retailer’s automated DR participation needs.

With Link deployed, Phoenix can now ensure that each  and every called event is handled quickly and completely, with no delay or chance of human error. This guarantees savings from curtailed energy usage and can provide additional customer savings by reducing or eliminating resources that were designated for manual curtailment. And because the process is now completely automated, customers have an opportunity to realize greater savings (and earnings) through participation in DR programs with dramatically shortened lead times.

and every called event is handled quickly and completely, with no delay or chance of human error. This guarantees savings from curtailed energy usage and can provide additional customer savings by reducing or eliminating resources that were designated for manual curtailment. And because the process is now completely automated, customers have an opportunity to realize greater savings (and earnings) through participation in DR programs with dramatically shortened lead times.

To date, CPower Link’s automated DR has performed flawlessly in this summer’s real-world, real-time events. While all the data aren’t in yet, PhoenixET expects its customers to see notable improvements in building energy savings, as well as revenue generated from utility programs through their collaboration with CPower. In a limited release, over a three-month period, selected stores estimate a positive return on investment from utility incentives amounting to more than 140% of the PhoenixET solution costs.

About Phoenix Energy Technologies

As an IoT innovator in smart buildings and connected machines, PhoenixET controls, manages, and monitors assets such as HVAC, lighting, refrigeration, industrial, and consumer-facing machines to do smart things such as alert, measure, and command to automatically correct or predict the need for service. Phoenix enables retailers, universities, grocery stores, theaters, and many other industries to accomplish their savings goals by providing best-in-class software that monitors and controls assets with minimal additional hardware.

Case Study: UMass Amherst – A Revolutionary Approach to Sustainability Yields Revolutionary Results

State-of-the-art battery storage, an innovative solar PV system, and “stacked” demand management programs provide energy savings, steady revenue, reduced greenhouse gases, and grid reliability for

this revolutionary institution.

Case Study: Lake Gaston Water Supply Pipeline

Virginia Beach, VA – Faced with the prospect of losing hundreds of thousands of dollars in demand response revenue, this Virginia Beach site discovered a way to keep the money flowing without interruption.

THE CUSTOMER: LAKE GASTON WATER SUPPLY PIPELINE

The Lake Gaston Water Supply Pipeline, also known simply as Lake Gaston, is at the heart of the economic vitality of the City of Virginia Beach (see our City of Virginia Beach case study). Located west of the city, on the North Carolina border, Lake Gaston employs six vertical-turbine centrifugal pumps, each with a nominal capacity of 10 million gallons per day, to supply Virginia Beach with the 30 million-plus gallons of treated drinking water that its residents consume each day. (The high-capacity pumps give the station the flexibility to increase pumping up to 60 million gallons per day.) The water flows through a 76-mile-long pipeline (which includes six overhead river crossings) from the lake to facilities in nearby Norfolk for treatment.

Since 2010, Lake Gaston has participated in the demand response program offered by CPower through Virginia’s Department of Mines, Minerals and Energy (DMME). This program pays government entities market rates for curtailing their electricity usage during times of high demand on the grid. Participants save on their energy costs and earn revenue that can be reinvested in upgrades, energy efficiency projects, and more. Lake Gaston’s participation has earned them nearly half a million dollars since 2011 (see chart below).

Steven Poe, the city’s Water Master Planner, assumed management of Lake Gaston in 2015. At the time, Lake Gaston had already earned more than $221,000 in DR participation, and Steve understood he could count on a continuing and beneficial revenue stream. Unfortunately, he hadn’t counted on a court ruling that dramatically changed the role of emergency generation in demand response.

THE CHALLENGE: CONFRONTING THE VACATUR

In 2013, the federal Environmental Protection Agency (EPA) issued emission standard exemptions that permitted emergency generators to operate up to 100 hours a year for “emergency demand response.” Lawsuits from environmental groups, state governments, and commercial power generation groups challenged the EPA’s ruling, saying it would hurt air quality and grid reliability. In May, 2015, the United States Court of Appeals for the DC Circuit vacated the 100-hour rule (on procedural grounds). This vacating ruling, dubbed “the Vacatur,” would take effect on May 1, 2016.

The Vacatur threatened to have a disastrous impact on Lake Gaston’s DR participation—and earned revenue. Lake Gaston was designed to pump continuously and could not do so without the use of its diesel engine generator.

The Vacatur left Steve no choice but to withdraw his diesel-powered generator from the DR program. Without it, he not only faced loss of revenue from its participation, but potentially the loss of all DR revenue. If the generator could not be used to sustain pumping during curtailment, then Lake Gaston would not be able to curtail the required power during a called event without jeopardizing Virginia Beach’s water supply. The pumps, then, would also have to be pulled from the program, essentially shutting down the lucrative revenue stream.

Or would they?

Steve felt that the financial benefits of DR participation warranted a closer look for a creative solution. “When we realized we couldn’t curtail anymore with our generator, we didn’t want to miss out on the incentives,” he says.

But to reach their target, they would have to conduct a full shutdown. Could they shut the pumps down—and bring them back up—without damaging both pumps and pipelines? And if they could, would that be enough to continue in DR without damaging their savings and earnings?

THE STRATEGY: SHUT ‘EM DOWN

Full shutdowns are rare in nearly all industrial settings, but Lake Gaston had a precedent. In 2014, a 39-ton coal ash spill on one of the lake’s tributaries forced the pump station to shut down for about two months. This was the first extended shutdown of the pump station in its history and caused a great deal of concern. Lake Gaston was designed to maintain a minimum sustainable pumping rate of eight million gallons per day flowing through the pipeline to maintain water quality and prevent issues with start-up. When pumping resumed, Virginia Beach learned that the pipeline was resilient and could recover with minimal effort.

Using that experience, Steve and his team are able to shutdown the major energy consuming equipment at the pump station – including the pumps and industrial HVAC system – within one and a half hours of being notified of a DR event. They’ve learned that participation without their generator is worth the extra effort of executing full shutdown and start up procedures, which requires monitoring the SCADA system and gradual reduction and startup of pumps to prevent water hammer.

THE CPOWERED SOLUTION: DMME + CPOWER DEMAND RESPONSE

Steve and his team had proven that pumps could be shut all the way down and brought all the way back up, on demand, with no damage to pumps and pipelines. He could curtail his assets enough to continue to participate in DR. The question remained, though: Would it be enough? “We were worried,” Steve says, “that if we didn’t cooperate or couldn’t participate in the test or event, there would be a penalty.” That could erase any financial benefit.

Fortunately for Steve, he had Leigh Anne Ratliff, CPower Account Executive, working with him. Leigh Anne has been with DMME since the inception of the joint DR program, and with Lake Gaston since they enrolled in the program in 2010. (She also works extensively with the City of Virginia Beach.) No one is as familiar with the DR program and Lake Gaston’s participation than Leigh Anne.

Leigh Anne told Steve that, because Lake Gaston (and the City of Virginia Beach) participate through DMME’s demand response program, there would be no consequences for not participating in a test or event. “The great thing about the DMME contract with CPower,” Leigh Anne explains, is that you really cannot be penalized. You’ll never owe anything. The worst that can happen is you’ll earn zero dollars for that test or event.”

THE RESULT: $400,000+ AND COUNTING

With penalties off the table and a successful pump shutdown protocol established, Steve continued Lake Gaston’s enrollment in the DMME DR program. He has yet to see zero dollars earned.

“We’re committed to saving money and being good stewards of public resources,” Steve says. “CPower is very supportive and encouraging for us to participate, to meet our commitments. When I first stepped into this position and informed my supervisors about the program, we all thought it was just too good to be true. But it has really worked out, and we are happy to continue participation.”

| Lake Gaston Water Supply Pipeline—Demand Response Earnings | ||

| Delivery year | kWs submitted | Earnings in $ |

| 2010/11 | 1843 | $ 99,676.00 |

| 2011/12 | 1557 | $ 53,311.00 |

| 2012/13 | 1759 | $ 30,685.00 |

| 2013/14 | 620 | $ 10,670.00 |

| 2014/15 | 1548 | $ 27,137.00 |

| 2015/16 | 1661 | $ 61,267.00 |

| 2016/17 | 1337 | $ 24,353.75 |

| 2017/18 | 1340 | $ 44,085.73 |

| 2018/19 | 1258 | $ 58,536.69 |

| Totals to date | 12,923 | $ 409,722.17 |

Case Study: City of Virginia Beach

Virginia Beach, Virginia – Energy Manager’s determined pursuit of energy efficiency savings earned the city tens of thousands of dollars in rebates in just a few short years. (Download this case study as a PDF)

THE CUSTOMER: THE CITY OF VIRGINIA BEACH

Located where the Chesapeake Bay meets the Atlantic Ocean, the City of Virginia Beach is anything but a sleepy resort town. It is the most populous city in the Commonwealth of Virginia, and boasts an economy comprising tourism, national and international corporate headquarters, advanced manufacturing, military bases, and agribusiness.

Besides the beach (the longest pleasure beach in the world, according to the Guinness Book of Records), visitors are drawn year-round to Virginia Beach’s many renowned attractions, including:

- The Virginia Beach Convention Center the nation’s first convention center to earn LEED® Gold certification as an existing building from the U.S. Green Building Council;

- The Virginia Aquarium & Marine Science Center, which attracts 650,000 visitors a year and hosts more than 10,000 fish, mammals, birds, and reptiles representing more than 300 species from around the world; and

- The Virginia Beach Boardwalk, three miles of oceanfront access, bike paths, live entertainment, restaurants, shops, and a 12-ton bronze statue of King Neptune.

Keeping the Convention Center, the Aquarium, and 350+ city buildings running in top shape uses a great deal of energy. That means, Virginia Beach is a city that understands the value of world-class demand-side energy management in municipal operations.

THE CHALLENGE: PERMANENT ENERGY (AND COST) REDUCTION

Virginia Beach’s city government serves its citizens and visitors from more than 350 facilities citywide. By 2010, constant increases in energy costs incurred at these facilities had risen to $20 million a year, a total plagued with “lost” buildings and meter reading errors in the hundreds of thousands of dollars.

To address this and other issues, including utility billing, Virginia Beach created the position of Energy Manager and hired Lori Herrick, MBA, LEED Accredited Professional, to lead its energy initiatives and manage municipal energy expenditures. With $5 million from the city, an unexpected $4 million windfall from the U.S. Dept. of Energy, and a mandate to conquer the city’s energy challenges—Ms. Herrick went to work.

THE CPOWERED STRATEGY: FINDING READY KILOWATTS

Energy efficiency (EE) projects result in permanent energy reductions, which the city recognizes as arguably the cheapest, most abundant, and most underutilized resource available to local government. With this in mind, Ms. Herrick sought to find out more about an energy program being offered through DMME, the state’s Division of Mines, Minerals and Energy. The program in question promoted energy performance contracts (EPC) to significantly reduce energy costs through energy efficiency measures that meet a guaranteed level of energy savings.

Ms. Herrick began the process of enrolling city facilities in DMME’s EPC programs, but was soon faced with the complex challenges of identifying what facilities, and how many kilowatts, to enroll. Fortunately, she received another windfall. She was introduced to CPower’s champion of Virginia demand-side energy management, Leigh Anne Ratliff.

Ms. Ratliff has worked with DMME since 2007 to offer integrated demand response services on a performance basis with no set up costs to the state. Demand response programs pay organizations such as government agencies for curtailing, or reducing, their electricity usage during times of high demand. Government entities who participate in demand response both save costs on reduced electricity use and earn revenue for their trouble.

As Ms. Herrick soon found out, CPower has an additional strength: the ability to provide complete measurement & verification (M&V) services for energy efficiency projects, necessary to receive utility rebates and credits. More importantly, CPower has unmatched experience in finding additional kilowatts (kWs) all too easily overlooked in already completed energy efficiency projects—and successfully submitting those kWs for even greater returns on the city’s investments.

CPOWERED SOLUTION: FOLLOW THE DATA (AND FIND THE MONEY)

Because the permanent energy reductions resulting from energy efficiency projects can pay dividends for up to four years after completion, Ms. Herrick and Ms. Ratliff set about the task of unearthing four years’ worth of city files to find buried EE gold – kilowatts that others missed. Looking back, Ms. Herrick says, “We were determined… it was kind of a no-brainer, to go through the files of projects we’ve done and submit the information. We were analyzing these projects to make sure the payback was there… They gave us a lot of data that Leigh Anne could use to calculate our benefit to the grid and then give us a check for it.”

From the outset, Ms. Herrick considered no project too big to tackle, working to help the Virginia Beach Convention Center earn its LEED® Gold certification (see below). She also considered no project too small to enroll, at one point submitting a 7kW project. As Ms. Ratliff explains, “If she had it, she sent it. One building got a credit for $52 in 2017. We’re learning on the cost-benefit element of this, but Lori is always looking further, to get every bit out of it that she can. In that way, she’s revolutionized what people put into energy efficiency.”

SPOTLIGHT: VIRGINIA BEACH CONVENTION CENTER

The Virginia Beach Convention Center (VBCC) is the crown jewel among the city’s facilities. It was the first convention center in the state to receive certification from Virginia Green, the Commonwealth’s voluntary campaign to promote environmentally friendly practices in Virginia’s tourism and hospitality industries. As noted above, it is also the nation’s first convention center to earn LEED® Gold certification as an existing building from the U.S. Green Building Council. These certifications are increasingly important in the competitive convention planning industry, where the VBCC competes nationally. Customer awareness of, and insistence on, “sustainable destinations” plays a greater and greater role in siting conventions.

The VBCC is also a shining example of how state-ofthe-art EE projects can enhance a city’s energy budget as well as its national reputation. Nearly all lighting in the convention center is LED lighting, and the HVAC is controlled through a state-of-the-art Direct Digital Control (DDC) system that incorporates an automated demand response program to control spikes in peak electricity demand. The automation limits any impact to convention-goers and still saves energy dollars.

“Together, we developed a process to systematically go through the building to reduce demand with the least impact on customer events.” – Leigh Anne Ratliff

It’s also a shining example of how the city and CPower Engineering worked together to successfully address one of the biggest challenges facing active convention centers: controlling peak demand electricity and total kilowatt usage. Event load-ins and load-outs at VBCC can be particularly problematic because the bay doors open directly from the loading dock into conditioned exhibit space.

“The Convention Center was a very cool energy project, because people in that space change every day,” Ms. Ratliff explains. “Bay doors are open for hours at a time, a lot of bodies and boxes moving in and out. The open bay doors are a significant source of heating and cooling loss. So how do we control that without disrupting loadins and other convention-goers already onsite?”

The first step was to analyze the status of the bay doors during times of peak demand. The Center’s zoned DDC system, which controls the Center’s HVAC, was programmed to prevent the air conditioning from running in the exhibit halls if the bay doors were open. In addition, the DDC system receives power pulses from the electricity switch gears throughout the day. In the next phase, an automated demand response program was integrated into the DDC system. When the system reads that the Center’s demand is getting ready to peak, it automatically implements one of three phases. Phase 1 changes back-of-house temperatures by one degree. If demand continues to peak, it implements Phase 2, which changes back-of-house temperatures by two degrees, all the way to three degrees at Phase 3. This automated program reduces the demand on VBCC’s chillers, which in turn reduces peak electricity demand.

“Our CPower engineers worked with VBCC’s staff to understand how the bay doors and events taking place in the building impact peak demand and usage,” Ms. Ratliff says. “Together, we developed a process to systematically go through the building to reduce demand with the least impact on customer events.”

With its DDC system program finalized and firmly in place, the Convention Center was able to ease demand on the grid, with near-zero disruption to its customers’ activities. In fact, the Center saved an astonishing 15 percent off their peak during its first year. And since the price of electricity peaks along with demand, this translated into significant cost savings that they otherwise would not have been able to attain.

THE RESULTS: $87,000 AND COUNTING

CPower is instrumental in helping the City of Virginia Beach navigate the complexities of PJM energy efficiency credits and paybacks. CPower submitted the uncovered EE data to PJM and earned the city both savings and revenue. For the delivery years 2017 through 2022, earnings from PJM for the city will reach just over $87,000 (see chart), with the VBCC earning $40,000 alone. And the city’s just getting started. “We just got another big round of funding,” Ms. Herrick says, “so Leigh Anne’s going to be hearing a lot from us.”

LOOKING AHEAD: DEMAND RESPONSE

In November, 2017, the Commonwealth of Virginia retained CPower through 2020 to continue to offer integrated demand response (DR) services to state agencies and departments through DMME. Ms. Herrick worked with Ms. Ratliff to identify five city sites they believe could be the most eligible for DR: Judicial and correctional facilities, the Convention Center, the Aquarium, and the central plant. The Convention Center currently participates in CPower’s DR program and earns revenue. The remaining facilities are undergoing audits to better understand their suitability. “DR involves curtailment, and we have to be careful when and how we curtail,” Ms. Herrick says. “That’s especially true of the aquarium. I want to earn revenue for the city, but we also don’t want to be responsible for a fish fry.” There’s no doubt, though, that Ms. Herrick will find a way to make it work. Above all else, she and the city are determined.

CPower will support their energy goals at every turn, with an energy strategy custom-made to meet their unique requirements.

SAVINGS AND EARNINGS: CITY OF VIRGINIA BEACH/VIRGINIA BEACH CONVENTION CENTER

Projects include lighting and green building. Sites include Aquarium, Boardwalk, Convention Center, library, maintenance garages, recreation centers, fire stations, police stations, EMS administrative and training center, and arts center.

City of Virginia Beach |

|||

|---|---|---|---|

| PROJECTS | ESTIMATED DR (kW) | FORECASTED GROSS $ | |

| 2017/2018 | 14 | 185.67 | $14,820.89 |

| 2018/2019 | 13 | 173.24 | $17,869.86 |

| 2019/2020 | 11 | 170.24 | $9,283.28 |

| 2020/2021 | 7 | 87.17 | $2,434.65 |

| 2021/2022 | 2 | 38.36 | $1,865.51 |

| Total | 654.68 | $46,274.19 | |

Virginia Beach Convention Center |

|||

|---|---|---|---|

| PROJECTS | ESTIMATED DR (kW) | FORECASTED GROSS $ | |

| 2017/2018 | 2 | 172.52 | $13,781.49 |

| 2018/2019 | 2 | 172.52 | $16,374.31 |

| 2019/2020 | 2 | 172.52 | $9,497.01 |

| 2020/2021 | 1 | 40.95 | $1,143.73 |

| Total | 7 | 558.51 | $40,796.54 |

Combined Totals |

|||

|---|---|---|---|

| PROJECTS | ESTIMATED DR (kW) | FORECASTED GROSS $ | |

| Total | 54 | 1,213.19 | $87,069.73 |

Download this case study as a PDF

Tishman Speyer: Improving Tenant Experience through Demand-Side Energy Management

Stand anywhere between Fifth Avenue and the Avenue of the Americas from 48th to 51st Street in Midtown Manhattan and you’re bound to see hundreds of passersby gazing at the iconic sights of Rockefeller Center. If Gregg Fischer is one of them, however, he probably won’t be goggling at the usual tourist highlights—Radio City Music Hall, Christie’s Auction House, the skating rink, or NBC’s broadcast studios. He’ll be heading into one of the center’s ten Art Deco buildings to speak face-to-face with a tenant.

To Gregg, the tenant’s experience is everything.

As the Director of Energy Systems for Tishman Speyer Real Estate, Gregg is personally responsible for managing sixty commercial complexes nationwide. The 8.8 million square feet that comprise Rockefeller Center is just a piece of the more than fifty-million square feet of class-A commercial office space and luxury residential properties Gregg oversees.

“Have you ever seen a circus performer who simultaneously spins ten plates on his feet and arms and head? That’s what I feel like every day of my life,” Gregg says, describing his daily mindset in balancing his company’s needs with those of his tenants. “I make sure all the plates don’t crash.”

For Gregg, every day is filled with minute-by-minute communication with both his tenants and their operation, procurement, and accounting staffs and the departments within Tishman Speyer, from his own team in design and construction to property management as well as the company’s partners and investors.

“The more we innovate on the demand-side, the more the grid, our community, and our tenants win.”

—Gregg Fischer, P.E., Director of Energy Systems, Tishman Speyer Commercial Real Estate

A leading owner, developer, operator and fund manager of first-class real estate worldwide, Tishman Speyer believes sound demand-side energy management—the practice of modifying consumer demand for energy—is crucial to providing a stellar tenant experience. “The more we innovate on the demand-side,” Gregg says, “the more the grid, our community, and our tenants win.”

Gregg is quick to point out the fallacy that Class-A tenants breed Class-A headaches. He would know, since the vast majority of Tishman Speyer’s portfolio consists of Class-A commercial office space that houses high-profile tenants and guests on a daily basis. Informing and educating tenants about the types of demand-side energy management their buildings participate in and the benefit their participation has on the grid, environment, and community helps tenants not only cope with the shifts in energy use but embrace them. “Our tenants spend a lot of time at work,” he says. “The more they learn about our energy management practices the more connected they feel to the building. It makes for a better experience.”

Communication and education are the cornerstones of transparency in the commercial real estate industry. While his preferred method of tenant communication is face-to-face and one-on-one, Gregg also employs a host of mixed media approaches to explain why buildings participate in demand-side programs. “We offer free walking tours of our buildings. We do lobby info-graphic signs. We do elevator screen messages. We even have a tenant smartphone application. Communication is the building block to trust and the key to making [demand-side energy management] work.”

Before Tishman Speyer considers any demand-side energy project, Gregg evaluates the project’s potential for tenant and community disturbance and impact, the potential change the project may bring to the building’s asset value, and other aspects that can affect the project such as leasing and contracts as well as incentive programs.

“CPower has experts in every market to help distill down the key details for our national customers. That’s our job.”

–Michael Mindell, Sr. Account Manager, CPower Demand-Side Energy Management

When it comes to introducing and executing demand-side energy management projects at his company’s properties in New York and elsewhere in the country, Gregg isn’t the only one spinning multiple sets of plates. CPower and its team of energy experts are by his side, juggling platefuls of responsibility and communication to help optimize Tishman Speyer’s tenant experience.

A demand-side energy management company that serves more than 1,300 commercial and industrial organizations nationwide, CPower provides customized solutions that combine demand response, demand management, and distributed energy resources tailored to serve the specific needs of a given organization’s facilities. CPower’s creed centers on the conviction that no two buildings are alike and every organization is unique.

Among CPower’s national team is Michael Mindell, a veteran account executive who’s been involved in the demand response industry since 2001, two years after the New York energy market was deregulated by the Federal Energy Regulatory Commission. Michael serves as the primary contact for Gregg Fischer and coordinates with CPower’s teams in the various energy markets where Tishman Speyer participates in demand-side energy management to help present to Gregg the key information necessary to make informed decisions in a timely manner.

“The energy industry is highly complex,” Michael says. “Each energy market is different in their regulations and ways they operate their programs. CPower has experts in every market, including regulatory advisors and engineers with experience in hundreds of commercial real estate facilities to help distill down the key details for our national customers. That’s our job.”

“CPower does a great job of understanding things for us in a short amount of time. Then they come to the table with ideas and solutions.” Gregg says of the demand-side energy management company. “Michael and his team are an honest sounding board that helps me see things in a fresh and different way. Our relationship is such that they can offer very upfront opinions that make the case for doing something either weaker or stronger.”

That CPower operates in all six of the country’s deregulated energy markets and has extensive knowledge of the programs and regulations associated with each market is a big advantage when the time comes to evaluate demand-side strategies for Tishman Speyer’s buildings. “I don’t have the time to go through the fine print and evaluate each and every program. I rely on CPower for that. Michael and his team do a great job of digesting the details and explaining which programs in which markets we should be participating in and what the various impacts might be.”

In 2017, its first year working with CPower, Tishman Speyer had 34 commercial properties participating in demand-side programs in two energy markets: New York, where 25% of the company’s global portfolio resides and PJM, home of the world’s largest wholesale energy market. Through demand response programs, which pay organizations for using less energy when the grid is stressed, Tishman Speyer earned nearly $1 million in curtailment revenue during its first year while earnings in PJM approached $400,000.

In 2018, Tishman Speyer will expand its demand-side energy management participation to include the New England market. For Gregg Fischer, the expansion is about more than improving his company’s bottom line. “It’s my responsibility and Tishman Speyer’s responsibility to leverage the benefits of our demand-side energy management into an experience that tenants, visitors, and guests have never seen before.”

To Tishman Speyer, it’s all about the tenant experience.

Case Study: Virginia State University

Virginia’s Opportunity University:

successfully seized the opportunity to earn additional revenue for the school through demand response

The Customer: Virginia State University

Virginia State University (VSU), founded in 1882, is one of Virginia’s two land-grant institutions. It boasts a current student population of approximately 4,700. VSU’s 231-acre campus includes 11 residence halls, 18 academic buildings and a 412-acre working farm used for agriculture research. VSU features academic environments within six colleges and is ranked No. 12 institution in the United States for historically black colleges or universities (HBCUs) by College Choice.

Ms. Jane Harris, Assistant Vice President for Facilities and Capital Outlays, was enthusiastic about PJM Interconnection’s demand response (DR) program, which pays organizations for curtailing energy use during times of high demand that strain the region’s electrical grid. She felt VSU had a good probability of a successful outcome, generating revenue to fund needed campus upgrades. In 2014, she was given the go-ahead to enroll in DR.

Team of Professionals

To make sure the university’s DR participation had a successful launch, Ms. Harris built a leadership team which included the facilities management staff and building managers. The team was led by one of her project managers, Mr. George “Bubba” Bowles. Mr. Bowles brought deep knowledge of utility operations and was tasked with managing the project. CPower, represented by Ms. Leigh Anne Ratliff, brought unmatched expertise in PJM’s DR curtailment program.

Planning and Communication

Mr. Bowles developed a demand response action plan that included a survey of all campus buildings, and the energy technology available in each building. The campus infrastructure was not designed to curtail energy quickly and easily. Not every building was equipped with sub-meters and automated controls, and some generators could supply power for only emergency lighting. Nonetheless, Mr. Bowles felt that with proper planning, training, and communication, VSU would succeed.

Communication–specifically communicating the program’s benefits–proved to be the key component of the plan. Months before the first test event, which required the university to reduce their usage at a particular date and time, the leadership team undertook an extensive communication program that targeted the university’s building managers, campus facilities maintenance contractor, information technology staff, facilities inspector, campus safety officer, and Yourdonus James, Conference Services Manager, who schedules outside groups for events on campus. Each step of the plan was explained in detail, emphasizing the real and substantial benefits the university would receive from DR. As the test date approached, specific tasks were assigned to facilities staff and the safety officer that would help VSU meet their targeted curtailment goals, from turning on generators to turning off the breakers to entire buildings. Ms. James explained that she was concerned when first informed of the demand response program, but the actual test proved transparent with no noticeable impact on her clients.

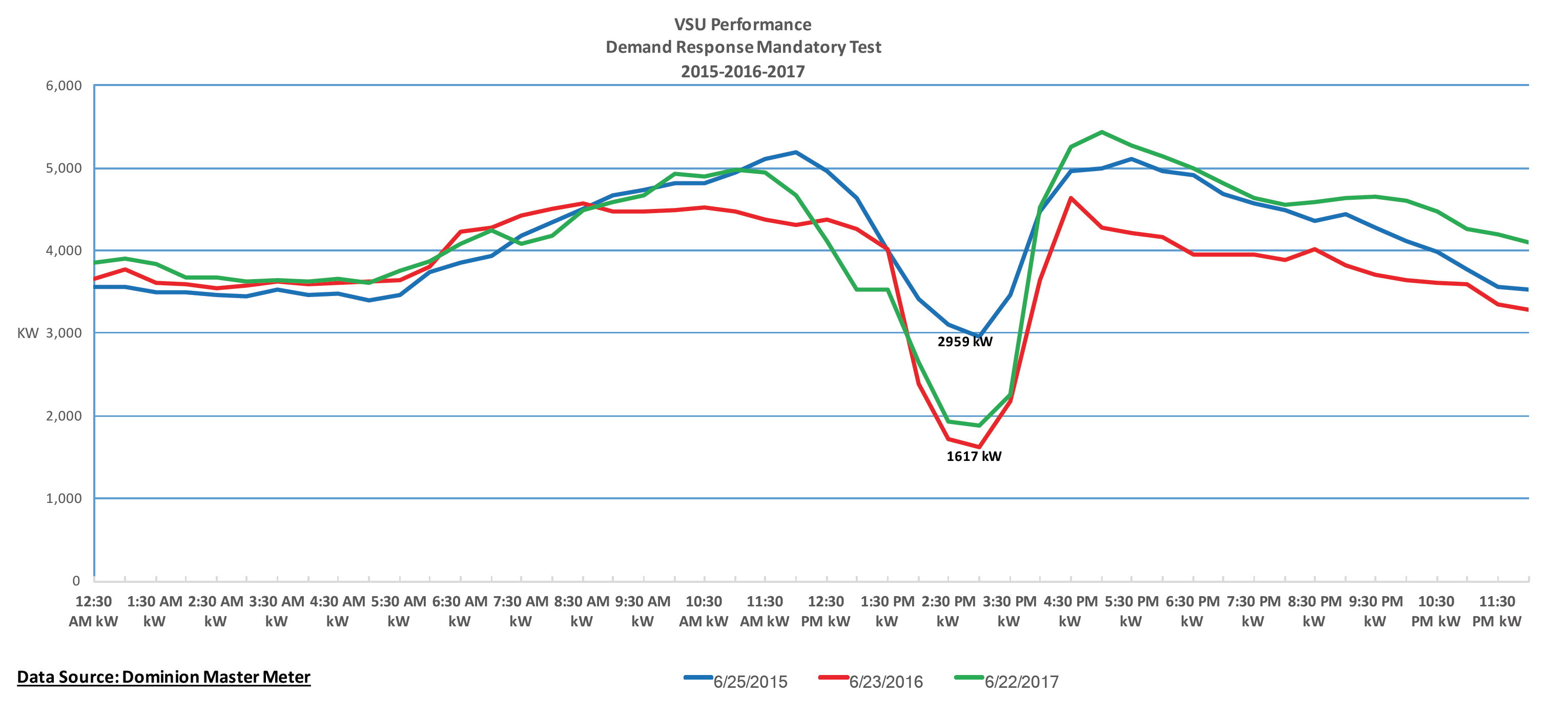

In June 2015, VSU participated in its first test event and exceeded its curtailment goal. In 2016, they set their curtailment goal even higher and exceeded that as well. In 2017, they set their goal higher.

“We make it easy for them to say ‘Yes’ by showing that it benefits them.”

— Robert “Bubba” Bowles, Project Manager

Record-Setting Reduction

The event test for 2017 was scheduled for a June afternoon at exactly 2:00 p.m. Around noon the plan, improved and streamlined over the past two years, was put into action. HVAC was cut off to 19 buildings, which were pre-cooled. In 10 buildings, energy could not be curtailed, so building managers enlisted the tenants to close blinds, turn off lights and computers, and schedule a late lunch to reduce usage during the test. Power to another 19 buildings was shut off completely.

As the plan proceeded, they faced an “11th-hour-and-59th-minute” challenge that threatened their continuing success. The team learned that at that moment, VSU was hosting 900 potential students at all academic buildings, including Daniel Gymnasium, one of the buildings targeted for complete shutdown. Not only that, but the students were to be sent out to explore any building of their choosing–many of them already curtailed–at exactly 2:00 p.m. Shifting gears, the team quickly “un-curtailed” Daniel Gymnasium.

At 2:00 p.m, with the temperature outside registering 87 degrees, VSU began its test curtailment. VSU had committed to curtailing their load by approximately 4 MW. By the time the event ended, of a total campus load of 6 MW, VSU curtailed 4.5 MW–an unprecedented 75% campus-wide load reduction.

Secret of Success

The one factor that all team leaders agree was critical to success is effective communication. By communicating clearly not only what had to be done, but why, the team was able to get buy-in from the entire campus community. Ms. Harris made it clear that the revenue generated by DR would benefit them directly–they would have the funds to do things that they normally wouldn’t be able to afford. Each building manager became an enthusiastic stakeholder, which assured campus-wide success. As Mr. Bowles notes, “We make it easy for them to say ‘Yes’ by showing that it benefits them.”

Rewards of Demand Response

Three years of increasingly profitable participation has funded a number of university facility projects. Chief among them are upgrades to two residence halls in the historical section of campus. The upgrades turned residence halls into destinations for which students now compete for assignment.

VSU has also been able to pursue energy efficiency projects that result in permanent curtailment and energy savings. Residence halls are being upgraded to highly efficient LED lighting, and generators are being upgraded to full building operation. Both upgrades, besides saving energy, have the potential for adding more revenue from DR participation.

Perhaps more importantly, the success of DR at VSU has helped create a culture of energy conservation and sustainability on campus. Faculty, staff, and students increasingly embrace programs such as recycling, energy conservation, and research into environmental programs and economic development. “Virginia’s Opportunity University” is also becoming “Virginia’s

Sustainability University,” true stewards of the earth that anchors their mission.

Download a shareable PDF version of this case study

Case Study: Desert Water Agency

2.5 MW of monthly demand response commitment gives the Desert Water Agency energy savings and additional revenue to offset costs.

The Customer: Desert Water Agency, Palm Springs, California

The Desert Water Agency (DWA) is a not for profit government agency providing water to the desert resort community of Palm Springs, in the Coachella Valley, as well as adjacent areas. Nearly all of the water that is used in the Coachella Valley comes from a groundwater basin, or aquifer estimated to contain about 30 million acre-feet of water. DWA pumps water using 29 wells spread throughout its retail area and delivers it to 23,000 water connections serving approximately 106,000 residents and businesses.

DWA embraces sustainable energy resources, including hydroelectric and solar, to power its pumps and generate energy savings. A solar field comprising 4,500 ground-mounted fixed tilt panels produces just over a megawatt of energy. The solar facility powers their Operations Center and Water Reclamation Plant and is projected to save the Agency and its ratepayers about $6 million in energy costs during its lifetime.

The Challenge: Tap the Demand Response Revenue Stream

The demand response program offered by CPower pays customers for reducing their energy usage upon same-day notification of a possible grid event. DWA understands the benefit of earning additional revenue by curtailing their power load and using that revenue to further offset energy costs. The key to DWA’s successful participation was technically implementing a curtailment program with the least possible disruption to its operations and its customers. Wells throughout the city that could participate in the program would be turned off when CPower issues a curtailment notification.

That left them with one important question: “Can we survive three to four hours of having wells shut down and still be able to refill our reservoirs to meet customer demand?”

The CPowered Strategy: One Well at a Time

Thankfully, with CPower’s help, the answer was “Yes.”

DWA chose CPower as their demand response provider to manage their participation in the demand response program. CPower provides a team of energy experts to review the Agency’s operations and energy goals. Together, DWA and CPower developed an energy management strategy that gives DWA the tools to optimize their participation in the program.

The strategy called for DWA to start with a small number of wells, to familiarize themselves with the curtailment process with minimal impact on day-to-day operations. As DWA’s staff became more comfortable with the process, more wells were added, until all eligible wells—25 of their total of 29—are now actively participating and generating revenue for the Agency.

“The CPower relationship has been outstanding… I fully trust them. The integrity is always there, they are always reliable and very knowledgeable.”

-Steve Johnson, Assistant General Manager

CPowered Solutions: Power Empowerment

Understanding the Agency’s preference for autonomy over automation, CPower empowered it with the tools to control its energy spend and demand response participation. The Agency can turn individual sites on and off at will upon notification through their supervisory control and data acquisition (SCADA) software to implement the custom-designed energy strategy developed with CPower’s experts. Perhaps best of all, the Agency can manage it all from their central Operations Center, without dispatching staff to well sites under a grid-stressing desert sun.

CPower collects utility meter data for each of DWA’s sites and supplies them with quarterly performance data. These data provide DWA with an understanding of each site’s base load value. The Agency can use these data to decide their optimum load curtailment commitment for each month of the program.

The Results: An Oasis of Cost-Saving Revenue

DWA typically nominates a changing rotation of eight wells each month into the program. The total monthly load drop amounts to about 2.5 MW. This is a significant commitment that helps relieve stress on the electric grid.

The program also provides DWA significant financial incentive for their participation. During a recent six-month period, May-October, they received $105,872.68 in payments for their participation. These incentives allowed them to further offset their energy costs, to the benefit of their customers.

Just as importantly, perhaps, DWA enjoys the total commitment of CPower’s dedicated California energy market experts. The Agency knows from experience that CPower will support their energy goals at every turn, with an energy strategy custom-made to meet their unique requirements.

Download a PDF version of this case study

Demand response contributes more than just sustainability to K-12 public school system

The Virginia Beach City Public School System is on a mission. At the heart of that mission lies a commitment to education, which you’d expect from the largest school division in southeastern Virginia. What you might not expect is how money earned from participating in demand response programs is helping fund the VBCPS’ drive toward academic excellence.

Ranked the fifth best large school division in the entire nation by GreatSchools, Virginia Beach City Public Schools (VBCPS) has earned a reputation for fostering a culture of outstanding academics.

That’s not all the school division has earned lately.

Since 2014, VBCPS has also earned over $250,000 through demand response and demand management. The increased revenue has helped pave the way for a sustainable future of energy efficiency and academic achievement.

Compass to 2020

VBCPS’ Charting the Course initiative was launched in 2015 to set the vision of school division over the next five years. The strategic framework includes four goals – high academic expectations, multiple pathways, social-emotional development, and culture of growth and excellence – and multiple strategies to guide this important work. This focus on excellence at VBCPS extends into their drive towards energy efficiency and sustainability initiatives across their entire K-12 campus system and facilities.

VBCPS understands the importance of conserving resources and protecting our environment. Among the nearly 70,000 students and approximately 15,000 employees are the often unique and innovative conservation efforts that can be found in every office and school in the division. As a testimony to this commitment, they have embraced Demand Response participation with support at all levels of the organization, from the office of the president to the facilities personnel, faculty, and students.

The Opportunity

VBCPS has been participating in the PJM Emergency Capacity DR and Energy Efficiency programs with CPower since 2013. They participate through the State Contract E194-1378 administered by the Department of Mines Minerals and Energy (DMME), which has joined forces with CPower to bring enhanced Demand Response services to Virginia.

VBCPS has 85 schools, 13 of which were registered in 2016 to participate in the Emergency DR program. The peak load of the 13 school campuses is 9.6MW of which they curtail 8MW when called upon to reduce load during times of grid emergencies. Since 2014, their efforts have brought in earnings of over $250,000, which they have used to fund additional efficiency projects to support campus-wide sustainability goals.

Consistent Success

VBCPS staff at each participating school takes ownership of their Demand Response participation and have consistently over-performed each season thanks to:

- Excellent cross-functional preparation and pre-season on-boarding with their facilities personnel and the CPower team

- End-to-end communications/notifications exercise and load drop test conducted by CPower allows the VBCPS team to identify potential issues (if any) and take actions to fix them

- Effective curtailment planning strategies to optimize load reductions with minimal impact on campus staff and students

- Complete buy-in, approvals and support from the VBCPS school division management

- VBCPS facilities team has sharp focus on setting up a detailed process for participation based on each school’s timecards and student schedules/events

- Team expectations clearly; communications plan includes command central (radio, email, telephone, text) with notifications as early as possible

Regular meetings and clear internal communications (via newsletters, posters etc.) - Team expectations clearly; communications plan includes command central (radio, email, telephone, text) with notifications as early as possible

- Regular meetings and clear internal communications (via newsletters, posters etc.)

- Every year pre-season, the VBCPS team proactively updates their Demand Response informational guide and set of procedures

- With a total of 8 staff in Central Command and 30 across the other schools; they maintain 2-3 trained staff per school, with 1 person handling a specific event at each school and the rest at back -up in the case of vacations/illness. Moreover, experienced staff members act as mentors/trainers for others that are new to the program.

Challenges and Lessons Learned

Some initial challenges included managing data from multiple utility meters as well as different building automation systems (BAS). However, the methods used above with site-specific planning allowed VBCPS to overcome the hurdles. Some sites have an Easy Button and use an automated approach while some utilize a more detailed hands-on approach.

In the end, clear communications and reliable equipment/metering are key factors for consistent performance. For instance, there was an emergency event called at the end of the season in 2013, where VBCPS delivered per their commitments even though school was fully in session. The schools also got the added benefit of earning energy payments from that event.

Forward-Thinking towards a Sustainable Future

Additionally, in 2014 the team pioneered the State of Virginia Energy Efficiency effort with lighting upgrades across the division footprint. They embraced the energy efficiency program, connecting CPower with their contractors to get the required information of qualified projects, and ultimately will earn close to $100,000 for their efforts.

Looking to the future, VBCPS has consistently added load reductions to their commitment to support grid reliability. They have added 8 more schools with an additional 2.8 MW of curtailable load to participate in the 2017 PJM performance season program, and are also exploring the PJM Economic DR program. Four new lighting upgrades from the spring of 2017 were submitted to the PJM Energy Efficiency program. The team at VBCPS are a powerful asset to demand response. By providing their operating procedures as a starting point to other participants, they have served as mentors for other schools – providing encouragement to their peers so they feel confident to take advantage of the program and optimize energy earnings and savings at other K12s across the Commonwealth.

Contact Leigh Anne Ratliff or anyone on CPower’s PJM team at www.CPowerEnergy.com/markets/pjm-interconnection-contact

Rhode Island Hospital: A “Shining Example” of Optimized Demand Response

When electricity prices in New England were on the rise in 2014/2015, Rhode Island Hospital braced for an energy spend they thought would lead a $1 million budget deficit.

With demand response and CPower’s energy management team in their corner, the hospital’s actual energy spend was much more favorable.

By participating in the ISO New England’s three demand response programs (Transitional Price Responsive Demand (TRPD), Real Time Demand Response and Real Time Emergency Generation) Rhode Island Hospital managed to offset their energy spend with the kind of efficiency that should make other New England hospitals take notice.

“We ended up breaking even,” said Marc Leduc, the Chief Engineer at the hospital’s on-site power plant. “A lot of it was due to those [demand response] programs.”

Founded in 1863, The Rhode Island Hospital is the principal teaching hospital of The Warren Alpert Medical School of Brown University. It is also a major trauma center for southeastern New England, and home to Hasbro Children’s Hospital, the state’s only facility dedicated to pediatric care.

In the mid-1970’s, Rhode Island Hospital constructed a cogeneration power plant on its grounds to provide electricity for the hospital’s day to day needs. Today, that power plant produces roughly 50% of the energy the hospital uses. Cost, particularly the cost of natural gas which the plant uses to create electricity, is a crucial factor in determining how the hospital manages its energy.

“Every dollar the hospital can save on electricity is a dollar that can be spent providing better medical care for the patients,” said Mr. Leduc. “Demand response helps keep us on budget by offsetting the cost of energy, especially during years when the price of gas is high.”

Bill Cratty, CPower’s Senior Technical Sales Associate for the New England region, initially enrolled Rhode Island Hospital in the ISO-NE’s demand response programs in 2007. Since then, he has worked closely with the Providence-based health care facility to help fine tune its demand response participation. Today he believes Rhode Island Hospital is a model to which other New England hospitals should look when considering how to offset their own energy costs.

“Rhode Island Hospital is a shining example of what a hospital can do to optimize their energy management,” Mr. Cratty said. “By participating in the TPRD program, they not only avoided purchasing electricity from the utility, but also got paid by ISO-NE for the amount of electricity they generated and bid into the day ahead market. The hospital consumed all of the electricity it generated. The payment it received from its demand response participation more than offset the cost to generate, so the hospital essentially received a significant portion of its energy usage at a negative cost.”

University of Maryland, Baltimore

A commendable effort to reduce energy load and lesson carbon impact.

In 2006, the State of Maryland passed legislation which required that energy consumption for all state buildings must be reduced by 5% in 2009 and 10% in 2010. The University of Maryland, Baltimore (UMB) was already ahead of the game; examining efficiency programs to find cost-effective measures to save energy and expenses on its campus.

Working with PJM Interconnection, the regional transmission organization (RTO), and Comverge, Inc., [CPower] a leading provider of clean energy solutions through Demand Response, Michael Krone, PE, CEM utility operations manager for UMB, found:

“By serving as our curtailment service provider (CSP), or broker, in the PJM DR programs, Converge [CPower] facilitated the reduction of our peak demand and overall consumption, which ultimately helped reduce our carbon footprint and emission levels. Comverge provided the resources to monitor real-time market pricing, develop load profiles, and create customer baselines. Comverge’s graphical tools have been invaluable to our success in the PJM DR programs.”

UMB enrolled in Comverge’s Real-Time Economic Load Response and its Reliability Pricing Model (RPM) programs. These programs offered assistance from energy analysts and delivered load profiling and IT support, consumption analytics and graphics, and other conservation initiatives.

Strategies

With the help of Comverge [CPower], UMB implemented strategies that reduced its energy load and helped meet the new legislative requirements:

- Using an existing 20,000 ton-hour/2,000- ton output thermal storage system to shift air conditioning loads from daytime on-peak operation to nighttime off-peak operation.

- Remotely controlling lighting in public areas and turning off all non-essential lighting during periods of high demand.

- Switching lighting and HVAC loads in real time via remote control from occupancy sensors local building automation systems.

- Temporarily raising HVAC return-air set points for 30 minutes or less to reduce cooling demand. Since the level of thermal inertia for a building is typically 45 minutes or more, this effort is transparent.

- Placing a portion of chilled water production on a current limiting mode for 30-minute periods. To ensure this activity remains transparent to the building occupants, only a fraction of overall production is in conservation mode at any given time, and the operation shifts between facilities.

- Deploying a Building Automation Network that monitors and controls the individual automation system(s) in each building from a central location.

Results

UMB reduced its load by more than 20,000,000 kWh in just two years. That’s the equivalent of two months of the school’s electrical consumption, or powering 10,000 homes for the same period.

“University of Maryland, Baltimore is a great example of what just one campus can do to reduce its energy load and lessen its carbon impact. The university should be commended for its innovation and forward thinking.”

─ George Hunt, Comverge senior vice president, Commercial Sales